Streamline Production with Azure IoT Operations

Modern factories produce vast amounts of data. But, bringing that data to good use, to optimize planning, streamline production and gain deeper insights into processes to optimize them, remains a challenge. We explain how data operations tools like Azure IoT Operations can help to transform raw production data into valuable information for manufacturing companies.

Transforming raw data into information

Modern manufacturing sites with oftentimes complex automated production processes produce terrabytes of data, sometimes daily. Just storing the raw data in a database or a datalake and trying to extract insights out of it is time consuming, causes a lot of effort and is a potential roadblock for fast realization of digital use cases.

The problem with raw process data is, that it is not normalized or standardized and often lacks context. Although a single process value can be used for simple monitoring, deeper insights can only be gained if process values can be correlated with other data and information like machine failures, environmental data or order information.

Normalization helps, when it comes to analyzing the data: Naming conventions, standardized units and timestamps allow data scientists to do their work more efficiently. They might not have a direct connection to the process. Therefore, they need additional context such as the units of measurement of the datapoints and a clear assignment to the data sources.

The following steps show, how connectivity solutions can help to improve data quality to enable data driven use cases:

With machine connectivity solutions that provide means to transform and normalize data like Azure IoT Operations, we can abstract from the differences between the plants and machine manufacturers and reduce the effort required to roll out use cases to other plants.

Connect & Get Data

Getting access to the raw data is the first step. Connectivity solutions support machine protocols to directly connect to the machines, e.g. via OPC-UA.

Transform & Normalize

In the transformation and normalization step, raw data can be transformed to common units of measurement and defined data types.

Standardize

The use of standard data models helps to abstract from the differences between machines from different generations or different manufacturers. This step is crucial to harmonize data from different sites and to allow for scalability of faster roll-out.

Publish to Unified Namespace (UNS)

By publishing normalized and standardized data to a UNS, this data gets additional context from the topic hierarchy. It is easily accessible for other interested clients and systems in a company and allows for faster problem solving and use case realization.

“MaibornWolff has been instrumental in shaping our product journey. Their commitment to sharing deep technical, industrial knowledge and providing invaluable feedback through testing has been pivotal in shaping Azure IoT Operations.”

Ansley Yeo, Principal Program Manager, Microsoft

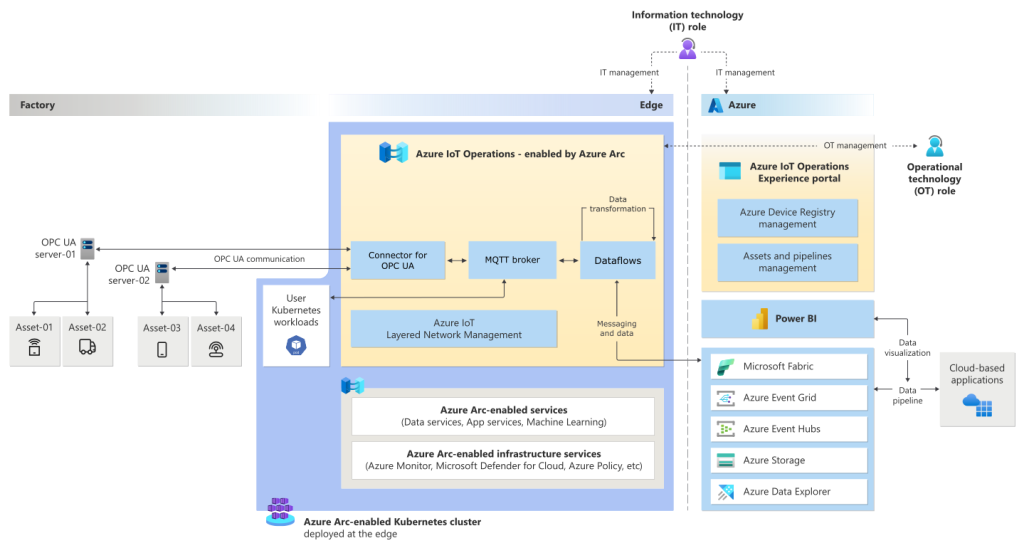

Building a data plane with Azure IoT Operations

We leverage machine connectivity tools that can connect directly to machines and processes and provide data transformation and normalization as close to the data source as possible. The use of standardized data models to harmonize data for example across similar machines from different manufacturers is another feature.

Besides this “DataOps” functionality Azure IoT Operations also includes the highly available and scalable MQTT broker Azure IoT MQ which can be used to build a Unified Namespace based architecture. With these capabilities Azure IoT Operations makes it possible to publish normalized data from the edge to a Unified Namespace running inside Azure IoT MQ. This potentially makes data accessible to all other interested clients and systems in the company.

Collaboration with Microsoft

We have worked closely together with Microsoft during the development of Azure IoT Operations and continue to do so. From our work with manufacturing clients, we know what they want and need to make better use of their production data. We shared our learning with the Microsoft product group at an early stage and provided constant feedback during the development and private preview phases. Due to this collaboration, we already possess deep knowledge about Azure IoT Operations.

Key features of Azure IoT Operations

It is built from ground as a Kubernetes-native application.

It Includes an industrial-grade, highly available and scalable MQTT broker that powers event-driven architectures and can form the foundation for a Unified Namespace.

It is highly extensible, scalable, resilient, and secure.

It lets you manage edge services and resources from the cloud by using Azure Arc.

It can integrate customer workloads into the platform to create a unified solution.

It supports a GitOps- and IoC-based approach for deployment and configuration.

It natively integrates with Azure Event Hubs, Azure Event Grid’s MQTT broker, and Microsoft Fabric in the cloud.

Building a Smart Factory is more than connecting machines

When working together with our customers on their Smart Factories, a fit gap analysis is always part of our approach. We take a close look at the existing application landscape and examine if tools like Azure IoT Operations can fill the gaps or if additional components are necessary for example to connect to legacy devices, that do not provide their data via OPC-UA.

Even though quality data is the basis for actionable insights, building a Smart Factory is more than connecting machines, and providing access to data. Besides the data layer the infrastructure is key success factor for digital transformation and has significant influx on the operability, scalability and security of the Smart Factory.

When a company is starting to plan their digital infrastructure, several requirements and constraints influence what an overall Smart Factory platform based on tools like Azure IoT Operations should look like:

On the one side there are requirements that are often specific to each company. These requirements include aspects like use cases and workloads or industrial protocols that need to be supported. Another aspect is whether multiple development teams will work on the platform.

On the other side there also a specific constraints and requirement from infrastructure, security and networking perspective. Examples would be topics like network segmentation, existing digital infrastructure or security guidelines that need to be considered.

No more PoCs.

Instead build a MVP.

Building a smart factory is as much about people as it is about technology. Even the most flexible and scalable infrastructure will be useless, when the people are missing that define and build use cases that crate actual value for the users and the company. When we work together with manufacturing clients on their Smart Factories, we follow a 4 step approach that reflects this and brings together people and technology:

References

Our digital projects

We work hand in hand with our customers from different sectors and industries.

Due to legal reasons, unluckily we can only provide the following references in German as they were seen by the customers. Please use the translation function of your browser.

Planning systems: Optimizing the capacity utilization of pressing plants

Our customer has an extensive portfolio of components and processes them in various pressing plants around the world.

Siemens: AI demand prediction platform for industrial production planning

Inventory costs are a major cost factor in production for an industrial company like Siemens. The AI Demand Prediction Platform, which can be used to predict future demand for products, is intended to provide a way of optimizing these costs.

Our vacancies

Do you like the way we work?

Click through and see if there are any exciting tasks for you.

Learn more